About 55 per cent of the container fleet is currently sitting in various ports or on water, as against a normal average of approximately 30 per cent, leading to less availability of containers globally and troubling exporters, including those in India, according to the Container Shipping Lines Association (India) (CSLA).

The container shortage faced by Indian exporters is thus a global problem, not country specific, CSLA added.

“From the beginning of July 2020, after months of lockdown, the US and Europe went on a buying spree and started importing big time from India, China and the Far East. At the same time, Indian imports dropped due to low consumer demand locally and certain restrictions placed by the government on imports from China. This created a major equipment imbalance as export demand for containers far outweighed the import supply,” CSLA Executive Director Sunil Vaswani said.

“The pandemic thus distorted the demand and supply situation. This distortion in demand and supply, with its resultant impact on costs and rates, did not happen just in the case of India but in the case of the rest of the world too”, Vaswani explained.

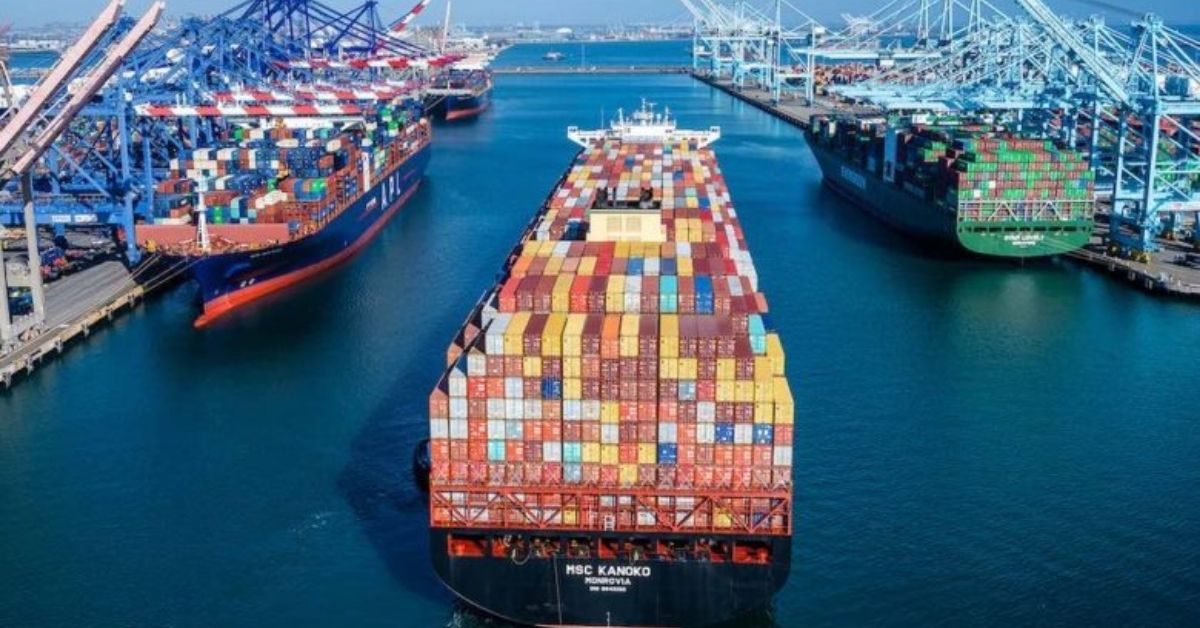

According to CSLA, congestion at transhipment ports like Colombo and Singapore, in some of the major ports in China and Europe, and the key gateway ports on the west coast of US like Los Angeles and Long Beach further aggravated the situation by increasing the turnaround time of vessels and containers, which eventually impacted the availability of boxes in Asian countries, including India.

“North America for instance, continued to face a 40 per cent equipment imbalance. In other words, out of every 100 containers entering North America, just 40 moved out”, Vaswani said.

Meanwhile, the Federation of Indian Export Organisations (FIEO) said that container shortage, non-availability of vessels and high container freight have affected exports as well as profitability of exporters.

“The situation was slowly reverting to close to normal before the second wave, but it has again aggravated. The waiting time to get a container is now again increased to 10-20 days and instant availability attracts over 100 per cent premium. The demand-supply mismatch has encouraged few stakeholders to put regular bookings on hold for one reason or the other, and allocate containers to those who are paying premium,” FIEO said.

However, CSLA said pricing is an individual decision of each shipping line which depends on commercial considerations such as costs, demand and supply, market scenario, sales strategy, among others.

“While some shipments might require to be priced higher than others depending on the product or the urgency of the shipment, others might not. On the other hand, some lines might just price themselves differently and not have any tier rates.

“At the end of the day it all differs from line to line and the market continues to remain very volatile not just in India but across the globe. Besides, once the booking is issued and the delivery order released, generally there is no real delay as such in the allotment of the box,” Vaswani said.

While CSLA said that the shipping lines have placed new orders with shipyards to help further beef up their fleet, FIEO stressed on the need for local manufacturing of containers and releasing close to 50,000 containers which have been held up or detained by various authorities in Indian ports.

Source : Business Today