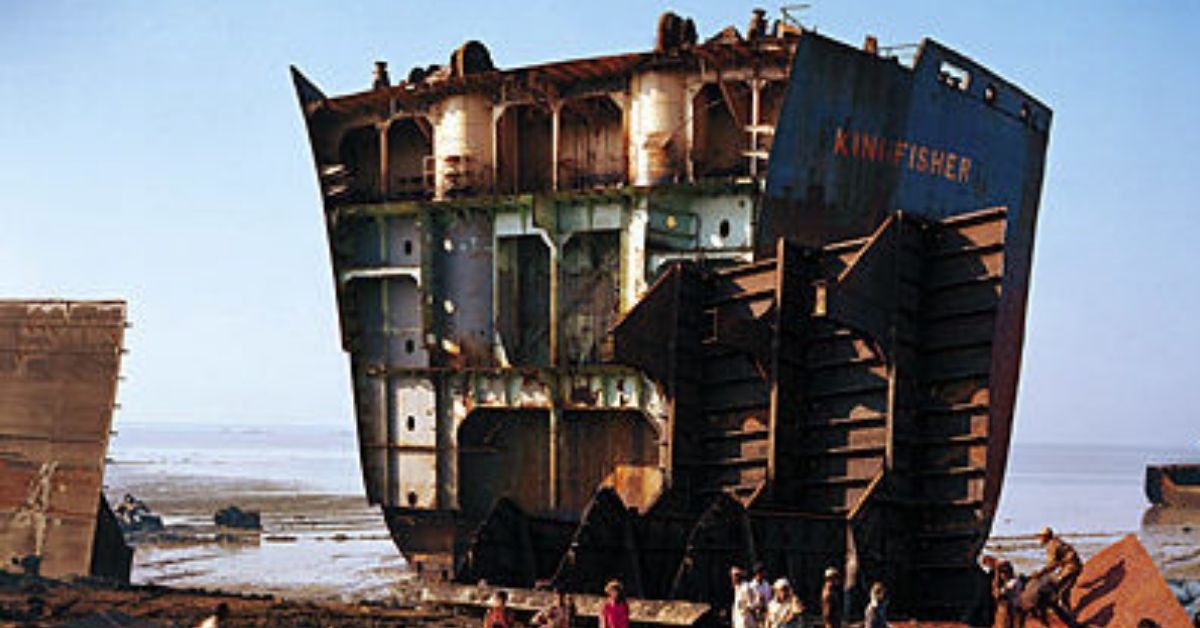

ASIA’S BIGGEST ship-breaking yard in Alang, in Gujarat’s Bhavnagar district, is staring at its lowest turnover in more than a decade, with only about 90 ships beaching in the first three quarters (April-December) of the current financial year, lower than the corresponding figures during the first two Covid years.

According to available data for the first three quarters in the last six years, 152 ships beached at Alang in 2021-22, 139 in 2020-21, 141 in 2019-20, 170 in 2018-19, 166 in 2017-18, and 195 in 2016-17.

In terms of weight of scrap, Alang logged about 8 lakh LDT (light displacement tonnage, which refers to the weight of the hull, machinery and equipment of a vessel but not including cargo, crew, fuel etc) in the first three quarters of the current fiscal. The Ship Recycling Industries Association (SRIA) said the total LDT at the end of the financial year may be the lowest in over a decade.

In recent years, the lowest turnover was in 2005-06, when 101 ships beached at the yard and only 4.80 lakh LDT was scrapped in the entire year. In 2007-08, the yard logged 136 ships and 6.43 lakh LDT. But in the following years, the average annual scrap generation remained about 2 million LDT till 2017-18, hitting a peak of 3.84 million LDT from 394 ships in 2012-13, according to SRIA data.

However, the output at Alang has been showing a steady decline since then. It slid below the 2 million LDT mark in 2018-19 when 219 vessels (1.77 million LDT) were scrapped. In the next three years, the LDT scrapped at Alang fell further to 1.62 million, 1.76 million and 1.45 million.

The sharp fall in numbers is seen as a fallout of the Bureau of Indian Standards’ (BIS) decision to change the norms for Thermo Mechanically Treated (TMT) bars. In 2012, BIS deleted TMT bars of over 6 mm diameter manufactured from recycled steel plates from its list of approved products.

“The LDT numbers tell the story and the direction Alang is headed into. Since the time the BIS deleted TMT bars manufactured from recycled steel from its approved category, the ship recycling industry is heading south, resulting in loss of thousands of employment opportunities, sizable revenue and high-quality construction material at affordable rates,” Vishnu Kumar Gupta, president of the Bhavnagar-headquartered SRIA, said.

The BIS made it mandatory to produce “certification” of raw material used for manufacturing TMT bars of over 6 mm diameter. The SRIA said this was not possible for them as major ship-builders in Japan and Europe source high-grade steel and other materials from multiple countries. Moreover, ships coming to Alang for scrapping would have been built two decades ago, so accessing records of raw material used for building them would be difficult, it said.

“From 2014-15, the steel re-rolling mills that manufacture TMT bars from steel plates cut from ships found it difficult to sell their products due to lack of ISI mark. This forced a number of mills in Bhavnagar as well as in Rajasthan, Madhya Pradesh, Maharashtra and Punjab, which would purchase steel plates from Alang as raw material, to down shutters,” said Gupta.

As the market for steel salvaged from scrapped ships shrunk, the ship recyclers were forced to sell it as scrap to be melted in furnaces.

“Furnaces melt all types of steel for converting it into new products. Ship recyclers are getting Rs 5,000 to Rs 7,000 per tonne less than what they would have got from re-rolling mills,” said Haresh Parmar, SRIA secretary.

He said this has reduced the Alang ship recycling industry to a “scrap industry”. “This despite TMT bars made from sheets of ship steel scoring higher on all parameters, including stress and strength tests,” he said.

But change in policy at home is not the only reason. The thinning margins of Indian ship recyclers have coincided with their Bangladeshi and Pakistani counterparts offering higher rates.

“In Bangladesh, steel generated from recycling ships accounts for about 40 per cent of the steel manufactured in that country. The share of such steel is quite high in Pakistan also. But in India, it is barely 2 per cent of the total steel manufactured. Therefore, recyclers in Bangladesh and Pakistan are offering higher rates for end-of-life ships,” said the SRIA president.

“Ship owners who want to scrap their vessels prioritise maximising the value of their ships. So, they tend to sell to those who offer the highest price,” said Parmar.

The impact is visible in Alang. “Barely 50 of the total 153 plots are active these days, directly employing around 7,000 workers,” said Gupta. “A few years ago, 40,000 workers used to work in Alang. While the government has set a target of doubling the output to 4 million LDT at Alang, it will be difficult to achieve this. Allowing marketing of TMT bars manufactured from recycled ship steel as a separate category of TMT bars can be a solution,” he said.