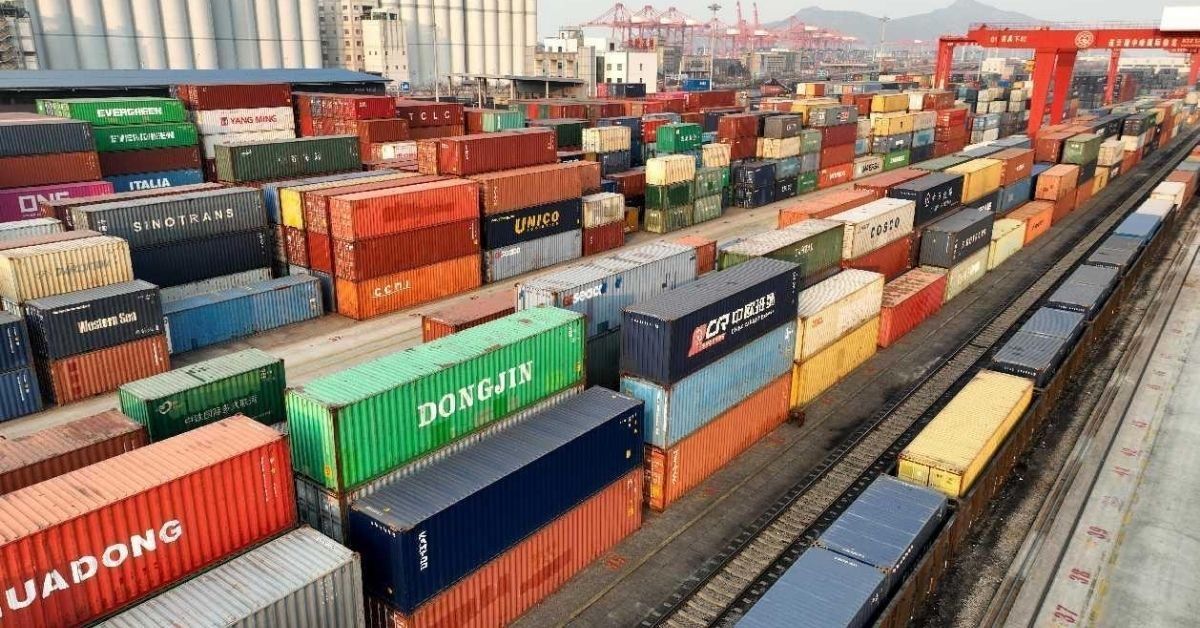

The study commissioned by D P World and led by Economist Impact revealed the emergence of major shifts in globalisation as companies across the world and in India diversify their supplier base and move manufacturing closer to home to hedge against geopolitical uncertainties.

Businesses in India are investing in creating higher inventory buffers to hedge against risks from geopolitical events, according to the ‘Trade in Transition’ study commissioned by Dubai-based logistic firm D P World and led by Economist Impact.

The report published recently revealed that 40 percent of Indian companies surveyed preferred increasing the length of supply chains to hedge against risks from current geopolitical events. Further, 47 percent of respondents from Indian companies found ‘exporting to new markets’ as the most effective means of making their trade operations more resilient as a demand-side strategy.

Similarly, from a supply-side strategy, 34 percent of respondents from Indian companies relied on ‘increasing the use of digital tools for improved inventory management’ to ensure resilience in their trade operations.

While it is evident that businesses in India can capture substantial price benefits by lengthening their supply chains to hedge against geopolitical uncertainties, this approach can also add to production costs, which makes it essential for companies to thoroughly evaluate their needs and options ahead of taking this route, the study pointed out.

To ensure supply chain resilience, executives in India are now investing in creating higher inventory buffers with a focus on protecting businesses from external fluctuations. According to the study, the average inventory buffer for some 27 percent of the companies in India is around 2 to 4 weeks, while 20 percent of companies surveyed have a buffer of about 1 to 3 months.

“This indicates a shift from the previously followed ‘just-in-time’ strategy to a more risk assessed strategy,” it said.

The study further revealed that currently only 16 percent of the companies surveyed in India are operating on the ‘just-in-time’ model.

Additionally, to reduce supply chain costs and risks posed by disruption of critical production inputs, around 33 percent of the companies surveyed from India are strategizing ways to expand into more stable and transparent markets.

Between April and September 2022, merchandise exports from India rose 17 percent while imports grew by 38.5 percent, compared to the same period of the previous year.

“The current edition of the ‘Trade in Transition’ report accentuates India’s opportunity to transform into a global logistics powerhouse,” said Rizwan Soomar, CEO and Managing Director, DP World Subcontinent.

“While geopolitical challenges and other disruptions have placed pressure on advanced as well as growing economies, India’s size, rich demographic proposition, and domestic consumption trends have largely insulated it from global shocks. These characteristics coupled with the country’s focus on enhancing trade efficiencies have cemented its position as a reliable partner to international businesses that are looking to diversify their supplier base while maintaining supply chain resilience,” Rizwan added.

From a global perspective, the key finding from the study is that 96 percent of the companies confirmed making changes to their supply chains due to geopolitical events. Business leaders in India too, resonate with the global sentiment with 58 percent choosing to diversify their supplier base and 14 percent shifting manufacturing and suppliers to the local market.

Speaking at the launch of the report at the World Economic Forum in Davos, D P World Group Chairman and CEO Sultan Ahmed Bin Sulayem said: “The report is tangible evidence of how globalisation is changing as companies look to meet new challenges. By bringing production closer to the final customer, firms can reduce the number of touch points involved in the supply chain and build greater resilience into the flow of freight cargo around the world. But the trade environment is always changing. The next challenge that will alter these trends is the looming economic slowdown in regional markets. Agility, real-time visibility, and end-to-end supply chain capabilities will be critical to ensuring companies can continue to find new efficiencies in an increasingly challenging environment.”

“The shift to regionalisation and reshoring has been sharp but unsurprising given the protectionist measures and diversification of the global trading system since the start of the pandemic. Among the most prominent examples of this is the US-China trade tensions over semiconductors, and although reshoring promises more control over inputs in the short run, it will lead to winners and losers. For example, as the US increases its production of semiconductors, it will increase its reliance on suppliers of mineral raw materials, such as Chile,” said John Ferguson, Practice Lead for New Globalisation at Economist Impact.