If you’re shipping millions of dollars’ worth of pharmaceuticals, high-end electronics, expensive sea-food, or precious metals, what would you be willing to pay for the ability to ‘ask’ your shipment where it is right now and whether it’s ok? What would you pay for a freight smart enough to raise an alarm before it spoils? Artificial Intelligence enables that and much more…

The world finds itself in the grip of an unprecedented pandemic. In many countries, the manufacturing of most commodities, apart from essential goods has come to a complete halt. Shipping and logistics operations too have been greatly affected, which is why industries world over are placing more emphasis on Artificial Intelligence (AI) and automation. In a nutshell, the idea of an autonomous supply chain that offers unprecedented information security finds immediate appeal.

But for those who are not tech savvy, a quick look at the basics first: The simplest way to define AI is to have a software mimic human behaviour that includes ability to learn, think and decide. If you’d extend that simplest of definitions to logistics, there are several opportunities that spring up to enable self-learning, correction and decision making in the logistics industry. Logistics in general has at least two distinct resources – the freight/cargo and the firms that move that freight. There is reassuring evidence that both firms and freight are increasingly becoming smart at their atomic levels. This accelerated adoption of technology is due to the inherent desire of knowing the status of freight – where is it, how is it and when will it arrive?

For a supply chain network that covers large geography, AI can provide the much needed granular visibility into where and how your cargo is, learn to recommend corrective actions such as route optimisation, intervention to save the condition of cargo and predict accurately the flow of goods through touch points. “Artificial intelligence is the ability of machines to make smart decisions with the available datasets. By implementing AI in logistics and supply chain, companies can save up to $2 trillion every year,” reveals Purnendu Shekhar, CEO, Cogoport.

“AI can be also used to predict future disruptions and events due to internal and external factors, how logistics capacity planning in warehousing and transportation needs to respond to any disruptions and events. At operating level, we can relate to the production planning with our daily order picking plan or manpower planning as fulfilment centre acts as a factory, informs Naveen Rawat, Co-Founder Holisol Logistics. A report by Mckinsey stated that the potential value of AI in this industry was around $1.2-2.0 trillion in 2018.

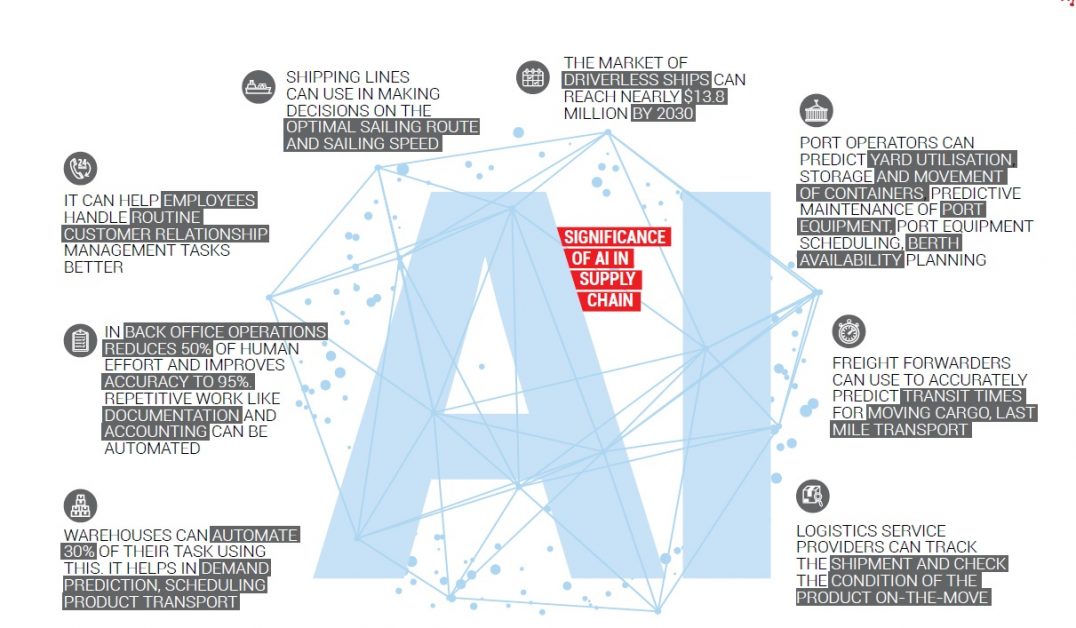

AI can enable the analysis of significant volumes of data while doing away with the room for human error. AI/ML can leverage massive data sets to first enable machines to perform various operation related tasks in nearly autonomous ways. For operations, such an approach can be used to streamline and automate the entire production life cycle. Predictive analysis can also be used to identify bottlenecks and problems thereby speeding up the process of resolving operational challenges. Automation can bring about a sea change in efficiency for data tracking, planning, scheduling and rescheduling processes. For instance, the implementation of AI helps ports make accurate predictions on the arrival of container ships. Machine learning can also help identify trends in shipping lanes and ports. “Shipping lines can make decisions on the optimal sailing route and sailing speed; port operators can predict yard utilisation, freight forwarders can use it to accurately predict transit times. A study by McKinsey shows that Logistics industry can save between $1.3 to $ 2 Trillion per year in economic value by integrating AI into manufacturing and supply chain processes,” shares Liji T Nowal, MD, ODeX India Solutions Pvt Ltd.

“The finance industry is employing AI in a lot of their functions requiring forecasting and analytical decision making. However, in logistics, a lot of intuition and guesswork is involved while predicting transit times during ship and air freight movements. We too can utilize the data loads available with us in creating machine learning models that could predict average daily transit time in advance. This would help freight loaders in planning their operations efficiently. Additionally, if we could incorporate parameters like climate variations, traffic fluctuations, etc. in the model, we could do wonders,” suggests Surajit sarkar, COO, DLDS. Some of the greatest tools in marketing nowadays involves utilizing the customer sentiment harnessed through AI in placing and promoting products. Logistics could too utilize this customer-centric data to ascertain material shortages, demand, supplier status, and other issues.

Another great impact of AI in logistics is the ML assisted predictive analysis. This allows the customers and also the logistics managers to get answers for questions like when, where and why? For logistics managers tracking of drivers and consignment has become easy with the implementation of AI.

Taking a cue from AI being used in various industries:

- Ocado, a UK based online grocer, ships an astounding 3.5 million grocery items, within the course of a week, in a pre-global pandemic market. This warehouse is driven by AI fuelled bots. This borg like an ensemble of bots is straight out of a science fiction fantasy. For Ocado, it is humdrum effective reality. The machine algorithm for these bots recognizes frequently accessed items and those rarely ordered. In the warehouse, items are stacked in a manner that offers the utmost efficiency for order fulfilment.

- A fertilizer company is working on what is possibly the world’s first self-driven ship, similar to self-driven cars being used for road transport. Yara International ASA is set to unveil The Yara Birkeland, a 120-teu open hatch container vessel which will be powered by a 7-MWh battery. Similarly, Intel along with Rolls-Royce is also developing self-driving ships.

- Like the use of AI in streamlining manufacturing where it helps streamline maintenance and production. This is usually accomplished with the aid of image recognition and conversational interfaces. In a similar way, AI can also be used to develop smart roads. These roads can use sensors to detect traffic volumes and alert drivers accordingly. They can be used in sync with self-driving ships with the aid of vehicle to vehicle communication, leading to an optimal multi-modal supply chain.

- Data analytics is used by businesses to assess demand for a specific product in target regions. Similarly, one can also incorporate machine learning algorithms to predict inventory for a specific product in a warehouse. For instance, this would enable freight forwarders to predict if the average daily transit time is expected to rise or fall within a specific time period. AI can also offer insight into climate and operational factors that could lead to delays.

Let us see how AI is transforming the logistics industry:

Maritime safety and surveillance: The advances include how ports can be exerted on growing sizes of the vessels. Like –

- port equipment scheduling

- berth availability planning

- predictive maintenance of port equipment

A leading transportation and logistics firm has benefitted by collaborating with the AI startup MAANA. By implementing AI, the time spent on port omission decisions was reduced by 99.7%. The usual 6-hour port rerouting analysis was cut down to just one minute.

Augmented real-time decision making: Logistics involves repeated tasks that have huge input data. By the implementation of AI, complex decision making can be done within seconds. For example, decision of route, carrier and last mile transport.

Automated Warehousing:

“In warehousing operations, AI models when combined with Machine Learning, Natural Language Processing (NLP) and robotics can build analytical models to notice patterns and suggest actions like the renewal of stock items, finding the shortest walking route, and improved inventory positioning in the warehouse. AI combined with computer vision equipment could assist in assessing barcodes and thereby improving response times,” explains Surajit sarkar, COO, DLDS.

One of the biggest problems warehouses face is the unpredictability in demand for products. With AI in the picture, this issue can be easily solved through intelligent predictions from past data. All it takes is to install an AI system that is constantly fed with daily demand and supply data. Intelligent warehouses can also save transportations costs by avoiding regular transport of products to and from the warehouse. Machine learning (ML) algorithms are effectively reducing human efforts in inventory and warehouse maintenance. AI based algorithms are making these warehousing jobs effortless. Robotic assistance along with AI is being used in major logistics industries across the globe. Lastly, AI can also automate various back-office operations in the warehouse thereby avoiding human errors.

According to Vero Solutions, 30% of warehousing tasks can be automated. This is made possible by the usage of computer vision to recognise and organise the products. It is proven effective and successful in many warehouses like Ocado in Great Britain. AI increases efficiency and profits.

Autonomous vehicles:

“Autonomous cars are AI at its best. The car is self-aware at all times and several paradigms can be borrowed from AI to apply to the logistics industry. Even semi-autonomous cars now detect human fatigue and act on behalf of them. When tire pressures are low, the car is aware of its impacts on performance and can trigger self-inflation to mitigate. This ability to self-correct can be truly revolutionary for the logistics industry. For example, consider the transport of bananas. If for any reason, there is a delay in shipment and bananas start ripening, the sensors in the cargo can indicate the rising ripening levels as a basic step. Combined with AI and investment from logistic providers, additional cooling or ripening prevention techniques can be auto-initiated. Measuring the intervention time and charging appropriately for that intelligent service that prevents the loss of shipment would be tremendously useful for all parties,” explains Surendra Lingareddy, Director – Asia Pacific, Volteo.

Waymo, the American company known for the Google driverless cars is planning to build driverless trucks that can be used for transporting goods. Rolls Royce and Intel, the two leaders in their respective industries are collaborating to build driverless ships. Recently, OOCL, a Hong Kong based shipping line, completed a development process over a period of 15 weeks with MSRA, Microsoft’s AI research center. This process enabled OOCL to have cost savings of an astounding $10 million in the ensuing year. A report by Markets and Markets estimates that the market of driverless ships can reach nearly $13.8 million by 2030. Some of the advantages of driverless cars and ships include efficient fuel usage, optimized routes, and avoidance of human mistakes.

Although certain governments insist on the presence of drivers in the vehicle, the possible risks on each road can be avoided. For example, Rolls-Royce AI features includes identifying objects under water and monitoring engine condition.

In back office operations: The back-office is one area where AI has some of the most impactful use cases. By using robots for the back office works like documentation and accounting, it reduces 50% of human effort and improves the accuracy to 95% where humans can achieve only 85%. Leverton, an AI powered software company claims that their AI software can reduce 30-50% of human effort in logistics.

In demand prediction: AI based tools increase the accuracy in demand prediction and thus improves the inventory. They are smart to predict the availability of inventory and truck delivery beyond prices and optimised routes.

Improving customer experience:

Customer Relationship Management (CRM) that incorporates AI has the potential to take employee productivity in CRM activities to unprecedented levels. AI can help employees handle routine CRM tasks better. For instance, call analytics software can record important interactions in person or over the phone, generate transcripts, collect and collate time-stamped information, record references to phrases or relevant topics. Meetings can be set-up automatically with AI based calendar tools. Intelligent algorithms can also help target customers more effectively and bring about a quicker resolution to end-user problems. According to Gartner, at least 52 per cent of the telephone firms today use chatbots for customer relations management.

Voice assisted deliveries have improved customer experience. For example DHL logistics can be tracked through virtual assistants like Alexa. DHL has partnered with Amazon to use its Alexa services. Alexa has been taught through AI to answer questions from DHL customers about the estimated time of delivery, the current whereabouts of the package and so on. Another example is Cogoport, a logistics marketplace company that uses AI to help suppliers move their goods faster and cheaper. It also provides a wide range of services like easy quotation generator and invoice generator.

AI has also resulted in better work satisfaction for employees as they can be used in more strategic roles to solve more complex tasks, which require the human touch. Some use cases are where AI can automate auditing processes, verify documentation for compliance purposes, and use RPA for data migration.

Using big data

Vast quantities of information are generated through the movement of freight. Trucks generate gigabytes of information per mile that never leave the truck. Chartered carriers generate information they are unable or unwilling to share with logistics companies. Logistics companies have centralized information systems that collect and process information about routes that are their competitive differentiation, and their ability and willingness to share that information with supply chain managers is constrained, especially when they compete on price and, historically, have not seen customers willing to pay an uplift for information.

While there is a great deal of information trapped in the various bubbles in the logistics ecosystem, there’s also a lot of information that’s never collected. Freight in motion moves through environments whose available communications bandwidth is expensive, constrained, and unreliable, and carried by charters that are disincentivized to collect or share information. There is a tremendous opportunity to generate, collect, and provide vast quantities of valuable information, and to apply edge intelligence to capitalize on that information at the edge where it is generated. That is the most exciting thing.

A case in point is DLDS effectively mining big data: Surajit sarkar, COO, DLDS says, “DLDS is engaging Artificial Intelligence in streamlining its operations at each step and maximizes value for stakeholders. We have created superior AI models that collate our data and offer real-time freight movement to our stakeholders so that they can plan their delivery timelines in advance. We use a highly organized and streamlined central data repository system that collects data from all sources, starting from the loading of cargo to its final delivery. Specialized big data models are utilized to enrich this data, to access risks, issues and offer insights into improving cargo movement. We present such information as analytical reports to our customers every month, which enables them to improve their operations significantly.”

Artificial Intelligence is the key here as it can use this excess amount of data to intelligently predict various useful parameters. Here are some ways in which AI can help the logistics industry by using various data:

Improved cost of transportation

One of the biggest challenges that logistics and freight companies face is the excessive transportation cost due to poor route selection, unpredictable weather, delays in ports and rising fuel prices. This is where AI can help. There is a huge amount of data that is generated while the ship is moving on the waters such as wind speed, direction, engine power used, etc. Based on these data, an AI system can predict the optimal route and driving configurations to the captain who can make the corresponding changes on the journey. As a result, not just the cost of transportation will improve, but even the emission control standards will be adhered to due to better fuel efficiency and less pollution. This is especially useful because it is estimated that the growth of emissions from international shipping is going to rise by 50% to 250% by 2050, according to a study.

Improved port operation

Based on past transportation data and the data pertaining to the current whereabouts of the ships gathered through GPS and device sensors, efficient decisions can be made on terminal and berth allocation for the cargo. This helps logistics companies to minimize the time spent by the ships anchored outside the port and wait for an available slot.

- Improved prediction of the estimated time of arrival

Logistics companies have an abundance of data owing to the involvement of various stakeholders on a day to day basis. When such large quantities of data are processed using AI, it can have a significant impact on various parameters such as cost of transportation, improved port operation and better prediction of the arrival time of the ships.

Past data such as time taken to deliver a consignment, the average time spent by a ship on waters, the average delay in delivering a consignment are all dependent on various factors. When all these data are constantly fed into an AI platform, it can predict the possibility of delays in the arrival of a consignment. Marketplace platforms like Cogoport accurately provide real-time updates of your consignment online. The Hamburg Port in Germany has installed an AI-powered tool that pulls data such as vessel position and proposed driving routes. This helps in predicting the estimated arrival time of the ship which is of great help to the port workers who can be ready with their trucks at the exact time of arrival of the ship.

Real-time visibility

AI-based analytics tool enables you to bring your suppliers, service providers & carriers on the cloud platform to give real-time end-to-end supply chain visibility on a single screen. It can stimulate and forecast all KPIs (inventory, lead time, cost and more) of your supply chain and enables you to take the decision that is truly data driven, reveals Naveen Rawat.

As they say, supply chain is as strong as your weakest link. Today, the weakest link is to retrieve real-time information about your cargo. While advancements are being made, most of the world still operates where visibility happens only at specific points, e.g. on the tarmac, at the factory or at your customer site. In places where AI is being successfully applied, there is always ubiquitous presence of intelligence at the edge.

How to start using AI?

The gradual integration of AI technologies into a comprehensive and scalable logistics software system can be a good strategy at present. In the beginning, the focus should be on outbound operations, vehicle optimisation and sales forecasting, suggests Naveen Rawat, Co-Founder Holisol Logistics.

To begin the following are the questions that any organisation must answer before commencing any AI program, advises Liji T Nowal:

- Which are the areas of business where automation is required?

- What data do we have about these processes?

- What is the source of the data?

- What benefits can be achieved by implementing AI in these processes?

But, much also depends on the role of the company in the logistics industry. For carriers, we would recommend making vehicles and their subsystems smart. We talked about tires. What about trailers or containers that are smart enough to let you know when they’re empty? What about self-aware trailers that know that they are broken or stolen? For logistics companies, we would recommend making freight smart as discussed previously. There are also opportunities to make facilities smart to better track warehousing; if your warehouse is ‘smart’, you don’t need to conduct brute force reconciliations. We advise on making atomic level investments first, combine that with edge intelligence and gains can be made in quick order, suggests Surendra.

Opportunities/challenges in using AI

One of the biggest challenges is the traditional business model; logistics competition is usually price based, and the purchasing agents are measured on their ability to negotiate lower rates. But we are also confronted with a unique opportunity to rethink this, as supply chain managers are confronted by their pandemic performance and are required to evaluate supply chain resilience. This will create an opportunity to compete on the basis of visibility and intelligence.