Even as global trade is resurging in a post-Covid world, supply chain management has emerged as an integral component for businesses. An efficient and effective supply chain, with a robust logistics system at its core, mitigates supply bottlenecks, yields competitive edge, and enhances profitability. While the pandemic heightened the challenges for organisations and drove them to recalibrate their sourcing and distribution structures, Covid-19 also acted as a catalyst for change, accelerating the momentum for a technology-powered transition.

Through the pandemic, the e-commerce sector grew exponentially from 13% to 17% of total retail market, while paving the way for continued growth in the years to come. The Indian e-commerce sector is estimated to grow at a CAGR of 27% to reach the USD99-billion mark by 2024. The rise of e-commerce and the digital marketplace phenomenon are changing the dynamics of the market, both, in terms of buyer behaviour as well as business transformation.

Redefined benchmarks

Even as businesses adapt to the new normal, changing customer expectations pose a big challenge. Customers expect faster time-to-market, reduced defect rates and customised products with greater transparency and at a lower price. On the other hand, the e-commerce and omnichannel sectors, which were already picking pace, have received a significant push during the pandemic, further adding to the challenges for the logistics sector. Additionally, increased eco-consciousness and sustainability concerns have compelled businesses to adopt green supply chain management strategies. Alongside these concerns, companies are beginning to explore on-demand manufacturing which while being good for customers translates into more work for the logistics industry. These challenges have underscored the need for a robust logistics service. Businesses need a resilient and agile logistics service to not only anticipate risks and develop mitigation strategies but also quickly respond, recover, and thrive.

To thrive in the highly disruptive environment, businesses are re-examining their conventional operations and recalibrating supply chain strategies to improve efficiencies, lower costs and ensure sustainability. For this, an efficient logistics system can be a critical differentiator, and technology can serve as a key enabler.

Providing inventory visibility across channels, technology drives proactive management that is critical for both, business-to-business transactions, and direct-to-consumer sales. It has also accelerated the speed with which order volumes move both up and down the supply chain. Logistics companies can achieve speed, efficiency and resiliency demanded by today’s complex markets by integrating automation, digital connection, and cutting-edge technologies such as artificial intelligence and robotics.

Robots: The future of processes

The most visible application of automation in the logistics sector, robots are increasingly being deployed to execute processes across the logistics value chain. They offer far greater levels of uptime over manual labour, thereby providing significant productivity gains and profitability for businesses. Technological growth over the past few years have led to the development of new-age robots that combine AI, machine learning, better sensors and response capabilities. While in the past, robots were limited to industrial manufacturing primarily because they were not considered safe for people, the new age robots are not only safe but also perform an array of repetitive as well as complex activities.

New age logistics robots are designed to achieve proficiency that matches and exceeds human capabilities. These devices, backed with enhanced hardware and developments in AI, provide human-like dexterity, improved vision, and quick, agile movement. Logistics robots such as automated guided vehicles (AGVs), robotic arms, mobile robots, etc. cut around 70% of warehouse labour costs and help businesses function round-the-clock with minimal costs. Rapidly gaining acceptance in warehouses and facilities across the sector, the global logistics robots’ market is projected to grow at a CAGR of 16.4% to attain a size of USD17.82 billion by 2028.

Collaborative Robots: Safety assured

Like logistics robots, collaborative robots or cobots are a major trend transforming the logistics sector. Unlike conventional industrial robots which work for humans, cobots are robots that work alongside humans. They are designed to work with people and so safety is the key. Research shows that human-robot teams were 85% more productive than robots or humans alone. Cobots are designed to assist the human associates and not replace them completely. Their biggest USP is their low cost and ease of deployment that allows even small and medium-sized warehouses to deploy automation and reap its benefits.

Cobots are emerging as a necessity for large warehouses and fulfillment centers where accurate, consistent, and quick movement of goods is required. They are designed to significantly increase productivity, reduce wasted motions, generate labour savings, and improve the overall safety of a facility. Cobots are easy to integrate, create lower and flexible capital costs, increase accuracy, reduce human error and boost productivity levels. Unlike hard-programmed robots which lack agility to handle the number of diverse tasks that crop up during order-fulfillment, cobots are flexible, safe, and easily programmable. They can be programmed on-the-fly to accommodate shifting priorities within the warehouse.

Cobots are the workforce of the future for multiple sectors. Cobots come with truly amazing benefits that could revolutionize the manufacturing industry with their precision and endurance for any repetitive task. Further enabling the workforce to collaborate in a safe environment. ABB’s GoFa and SWIFTI cobot families expand the portfolio to create the most diverse cobot portfolio on the world. This will help accelerate automation and open doors to first-time users across multiple sectors, such as healthcare, logistics and retails including small and medium enterprises, which currently have low levels of automation on the shop floor. Cobots will significantly expand the potential for automation for every player in the industry.

Automation: Efficiency plus productivity

How do businesses thrive in a competitive environment? Automation of logistics operations is the answer. Automation of logistics operations offers multiple benefits for businesses. It reduces the drudgery involved by taking over tasks that are physically demanding and non-value adding while at the same time improving efficiencies leading to faster order handling and processing. Robotic automation has shown to deliver a demonstrable return on investment through higher throughput, combined with improved accuracy, thus cutting down the rate of returns and improving customer satisfaction.

A growing category of devices such as autonomous mobile robots (AMR), aerial drones, automated guided vehicles, automated storage, and retrieval system, etc. can be programmed to perform tasks with little or no human intervention. The automated devices help increase worker productivity, reduce error rate, cut down the frequency of inventory checks, optimise picking, sorting, and storing times, and significantly reduce long-term costs.

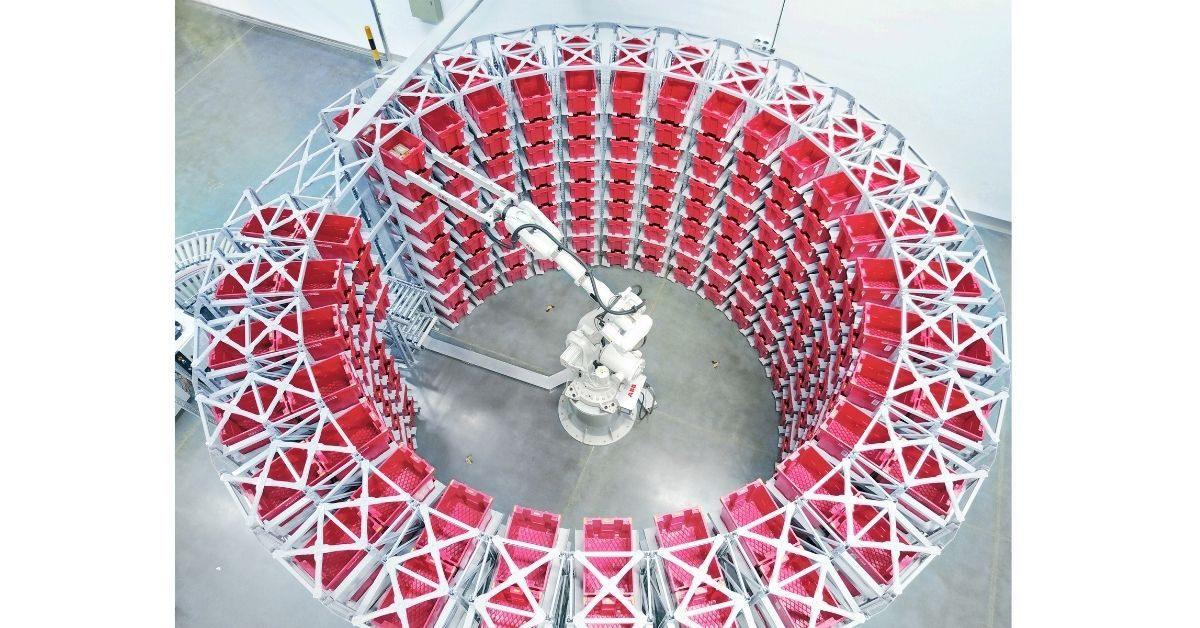

Automation of e-Commerce warehouses especially work on the basis of “Goods to Person” in most modern set-ups where a combination of multiple stacker cranes, sequencing systems and buffer creation systems help in delivering the goods from the racks in which it is stored to the dispatch agent either on First in First Out (FIFO) or Last in First Out (LIFO) or random sequence basis. ABB’s newly launched modular solution of FlexBuffer is an interesting innovation in Robot Storage and Retrieval System (RSRS), which helps in automating major part of the Goods to Person process in a modern warehouse.

Post the acquisition of ASTI robotics a global leader in AMR (Autonomous Mobile Robots), ABB will be the only organization to offer a complete automation portfolio of AMRs, robots, and machine automation solutions, from production to logistics to point of consumption. This unique selling proposition will prove a gamechanger for customers as they adapt to the individualized consumer and seize opportunities presented by significant changes in consumer demand.

Automation all the way

The fast-changing operating environment is forcing businesses to evolve and adapt. This has placed the logistics sector under severe pressure to deliver better services at ever lower costs. While the challenge seems daunting, automation can help businesses ride the wave of change. According to a recent McKinsey report, growing shortage of labour, increasing demand from online retailers and technical advances will be three game-changing supply chain technologies. Logistics companies must remain lean and agile to keep up with the competition, especially, to keep up with the speed of deployment. More automation in picking, packing, and sorting will serve as the catalytic factor to meet same-day delivery requirements.

Automation can also be leveraged to work around the challenges posed by labour; it allows logistics companies to offer better service and save money at the same time. For logistics companies to navigate the challenges of the future and operate and succeed in a highly volatile environment, it is imperative to upgrade their legacy environment through large-scale automation. Automation can help logistics firms improve efficiencies and achieve economies of scale and thrive in the face of stiff competition.

President Head of Robotics Discrete Automation Business

ABB India Ltd